COATINGS & TREATMENTS

HIGH DUST RETENTION. EXCEPTIONAL AIRFLOW.

COATINGS & TREATMENTS

Crosible is constantly investing in researching high quality coatings and treatments of filtration media.

PRODUCTS

CROSTEX (with ePTFE Membrane Technology)

What is CrosTex?

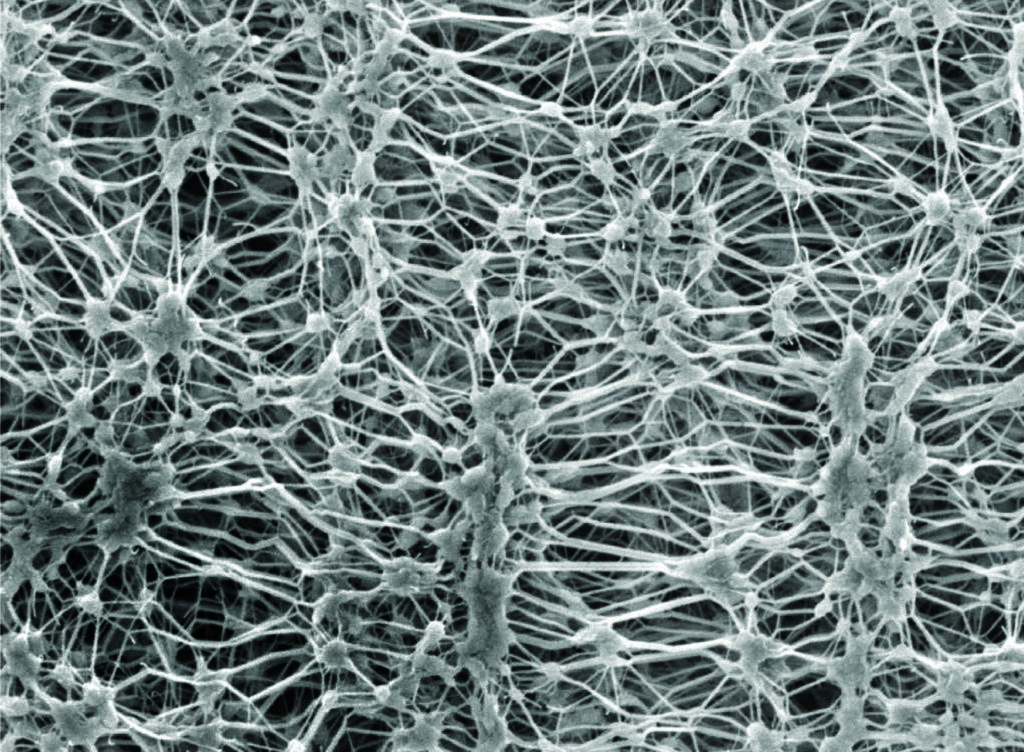

CrosTex is a micro-porous Teflon membrane (ePTFE) bonded to the surface of conventional filter media, to both woven cloths and needlefelts.

Why use CrosTex media?

Dust retention efficiency of 99.99% can be achieved with improved air flow, lower energy consumption and improved dust cake release.

1. CrosTex offers the highest filtration efficiency.

CrosTex will meet the most stringent regulation standards for emission control. The average pore size of CrosTex is between 0.05 and 1.0 micron. These microscopic pores are created in a three-dimensional membrane structure. The pores are smaller than most airborne or waterborne particles, yet large enough to allow for passage of gas molecules.

Due to the 99, 99% efficiency rate of the membrane, it is not uncommon to achieve emission levels of 0.01 mg/m³. Test results using CrosTex showed forty times less emissions than the standard needlefelt media.

2. CrosTex ensures lower operating pressure drops.

Depth-filtration verses Surface-filtration.

Conventional Depth Filtration

When using conventional needlefelt media, the initial layer of dust penetrates to a certain depth into media and then a layer of dust accumulates on the surface. The initial layer of dust is permanently trapped below the surface of the media. This works effectively in the initial stages of the filter process but later it causes a pressure drop. It could take hours or weeks to occur but at that point the advantages of CrosTex become apparent.

Depth filtration may not be effective on submicron particles, where bleed-through emissions causes loss of product. This is known as “puffing” – pin-hole perforations caused by the cleaning process.

CrosTex Surface Filtration

CrosTex allows a consistent air-flow rate throughout the life of the filter bag because the filtration process occurs on the surface of the media. The ePTFE membrane prevents dust particles penetrating the fabric and therefore avoids a pressure drop during the lifespan of the filter bag. CrosTex permeability rate is 8-12 CFM, which is much lower than conventional needlefelt (25-70 CFM) but the difference is more than compensated due to no pressure drop occuring.

3. CrosTex has excellent dust-cake release properties.

The ePTFE membrane has the smoothest, non-stick surface. Its hydrophobic property helps to discharge sticky moist dust particles which on conventional media would lead to blinding of the media.

Baghouses using CrosTex filter bags require 30% less aggressive pulse to discharge the dust. Pulsing at 4-5 bars instead of 6-7 bars results in less mechanical damage to the filter bag.

4. CrosTex offers greater airflow and lower energy consumption.

With minimal pressure drop during the life of the filter bag, CrosTex operates consistently at a higher air flow rate. The average 1:1 m³/m² air-to-cloth ratio with conventional media needs to be maintained but with CrosTex, it can be increased to 1:1,5 m³/m².

Where CrosTex filter bags are specified for a new baghouse, the size of the baghouse can be reduced, which means less capital and operational costs, ensuring greater profitability.

5. CrosTex is more cost effective.

Although CrosTex filter media is more expensive than conventional filter media, the benefits outweigh the initial costs because CrosTex has a longer life expectancy.

CrosTex membrane can be laminated onto the following media:

- Polyester needlefelt

- Antistatic (Epitropic) polyester needlefelt.

- Polypropylene needlefelt

- Homopolymer Acrylic

- PPS (Torcon / Ryton / Procon)

- Aramid (Nomex/ Conex)

- P84 Polyimide.

- Woven glass fiber

PYRO-FLO® NEEDLE FELT

PYRO-FLO® is a new range of high temperature needle felts yielding ultra-low, sub-micron particle retention.

Its Perylitic scrim rendering vastly superior strength, durability, and dimensional stability.

Boasting low Delta P properties has made this range an environmental must in combating environmental air pollution.

Need More Information?

Contact us today to arrange for a meeting with one of our filtration specialists.

CONTACT USWE ARE CROSIBLE

Our aim is to ensure that our clients’ environments are clean and green! Contact us to find out how we can add value to your business today.